Carbon2Chem - Exhibit to present the project

- April 21, 2022

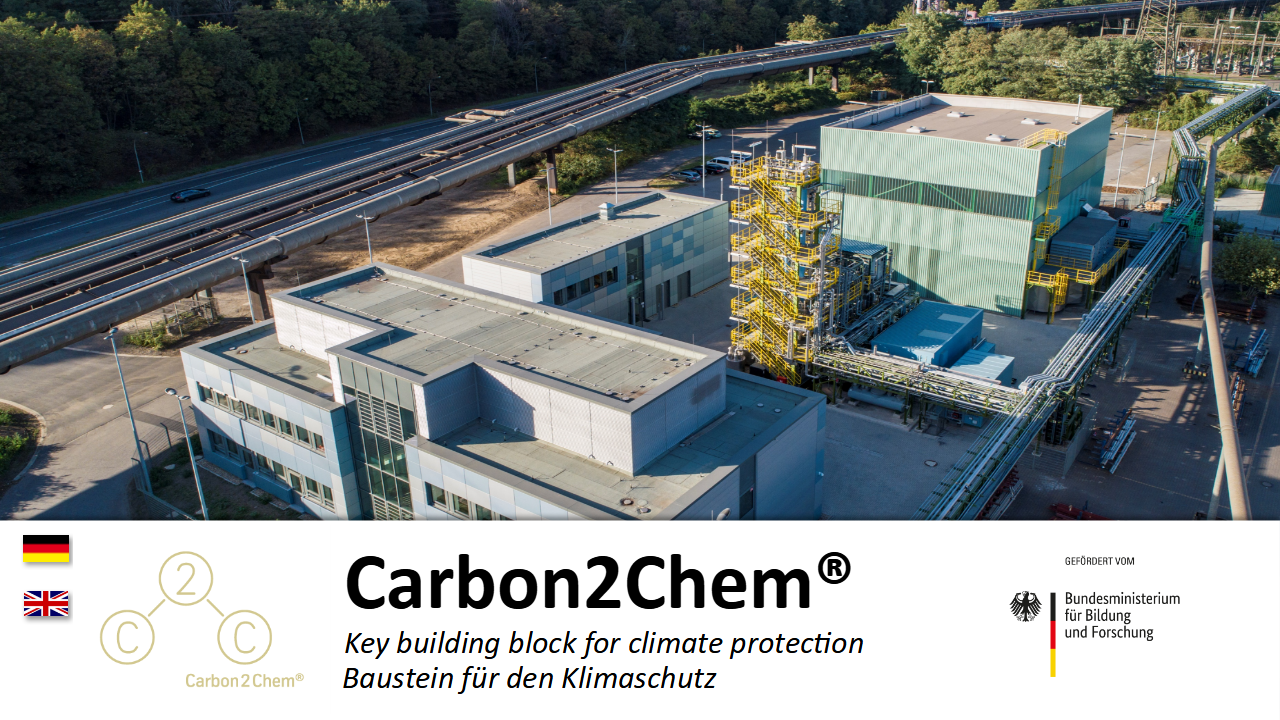

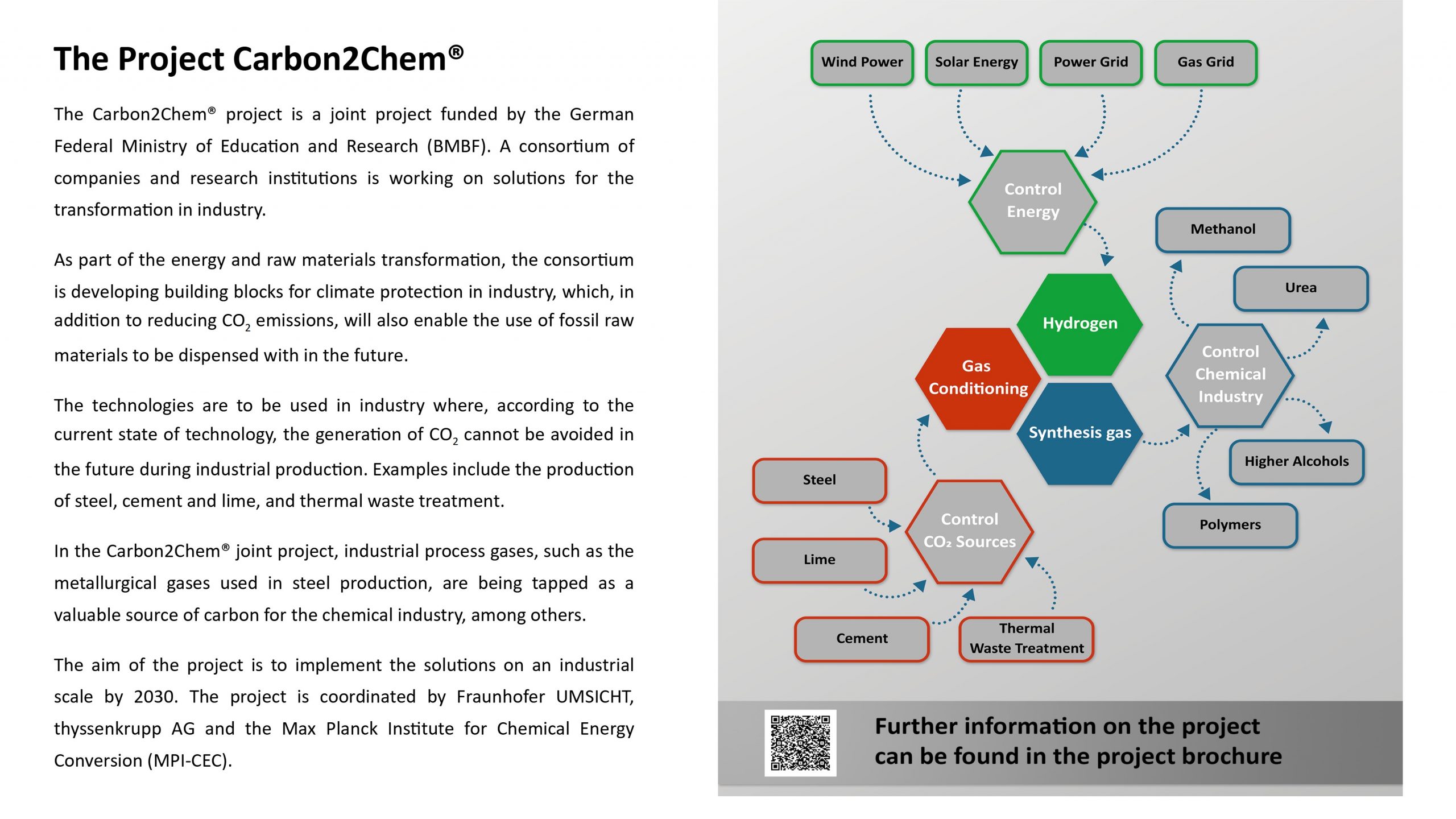

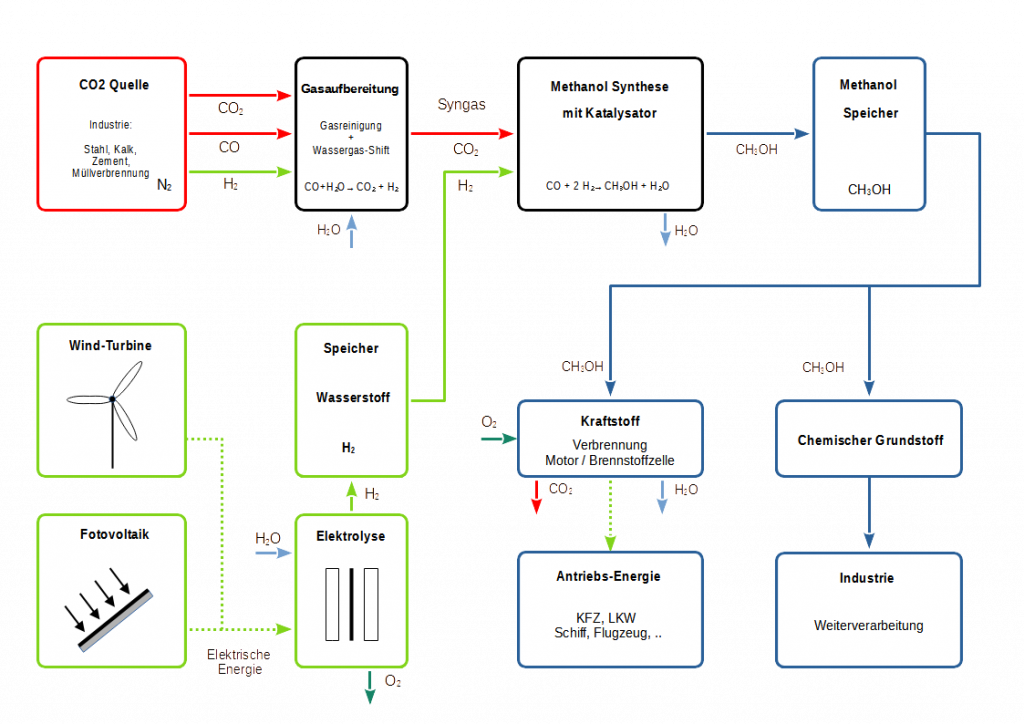

The Carbon2Chem joint project, a joint project by the Fraunhofer Institute UMSICHT, thyssenkrupp AG and the Max Planck Institute for Chemical Energy Conversion (MPI-CEC), aims to use industrial process gases, for example the metallurgical gases (CO, CO2, ..) from steel production, as a valuable carbon source for the chemical industry.

Exergia were commissioned by the MPI-CEC in Mülheim to create a concept for the public presentation of the project using a demonstration model and to realize this as an exhibit. The functional or illustrative model is intended to show the conversion of CO2 and green hydrogen into a chemical product (methanol or ethanol) and its subsequent use as a fuel and chemical raw material.

Conception of the Carbon2Chem presentation model

Carbon2Chem - Process components

- CO2 Source / Blast Furnace

- Gas processing

- Solar cell (renewable energy)

- Wind turbine (renewable energy)

- Elektrolyseur

- Methanol synthesis

- Chemical base material

- Fuel

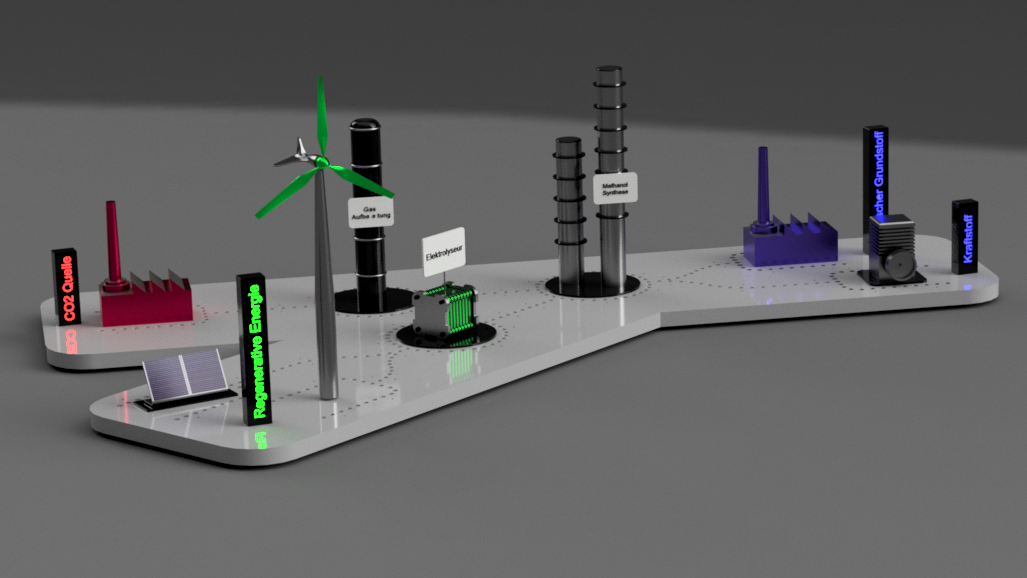

CAD models of a table and two base variants served as the basis for decision-making for possible structures.

In consultation with the client, the decision was finally made to create the exhibit in base variant B.

The original idea of realizing the process mapping via a miniaturized, chemical functional model was dropped due to the expected complexity of the structure as well as practical considerations regarding maintenance and safety requirements. Alternatively, a concept was developed that realizes the components as stylized, geometric miniature models and depicts their activation and the corresponding energy and material flows using animated LED light patterns.

By integrating a tablet with an appropriately developed app, both automated light choreography of the entire process flow and the activation of the individual components can be controlled in different modes. The app also provides illustrated background information on the entire project, the components and the process flow.

Construction of the Carbon2Chem presentation model

Specification

- Dimension 1500mm | 1000mm | 800mm

- Counter made of MDF painted white and black

- Indirect lighting under the edge of the table and the lower edge of the body

- Acrylic glass cover

- Components and illuminated signs 3D printing nylon, black

- Light animation using Arduino Nano BLE and 300 LEDs

- 15 inch Android tablet

- Communication tablet – Arduino via Bluetooth BLE

- Firmware (C++) for Arduino to control the LEDs, generate animated light patterns and Bluetooth communication

- Carbon2Chem app (MIT App Inventor) to display project information and switch on the light animation

Carbon2Chem - electronic boards

Tablet with Carbon2Chem app

Process animation

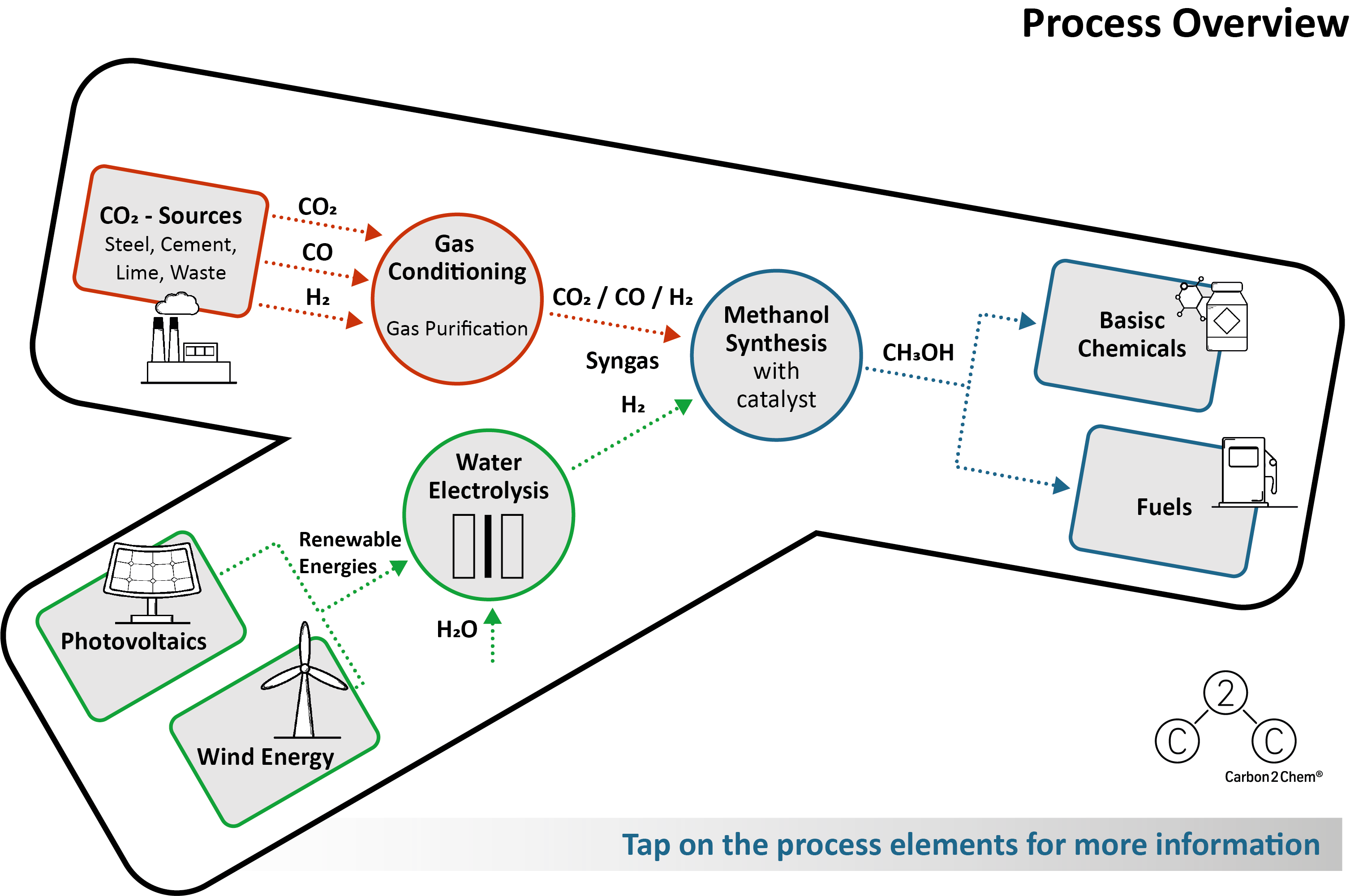

After switching on the presentation model, the Carbon2Chem app on the tablet automatically starts in process animation mode. By successively activating corresponding light patterns (flashing and shifting colored LED sequences), the material and energy flows from the CO2 and hydrogen source, through methanol synthesis, to the end products, fuel and raw material for industry, are visualized.

Component animation

The component animation is used to explain and provide background information about the individual components and ongoing processes using displayed graphics and texts. All components as well as the relevant material and energy flows are displayed in the “Process Overview” graphic.

After selecting a component, a new screen opens that provides further information about this component (information pages). At the same time, the corresponding component on the presentation plate is activated with its specific light pattern.

The information pages