Stirling engine with a stack-shaped structure

- November 9, 2023

Principle and previous development

Requirement

The requirement for a new motor is the ability to exploit temperature differences, such as those that occur as fluctuations in the outside air temperature in the day-night cycle, and at the same time achieve a mechanical output of approx. 10-100 watts.

At an assumed working temperature of

Tmax = 20° C = 293 ° K

and

Tmin = 10° C = 283 ° K

results in a maximum efficiency of

η <= 1 – Tmin / Tmax = 0,034

Under ideal conditions, a heat output of at least 30 watts must flow through the machine per watt of mechanical power generated. In real machines this value will certainly be a factor of 2 to 3 larger. In order to transfer this amount of heat, a correspondingly large dimensioning of the heat exchanger surfaces is essential and is the central design task.

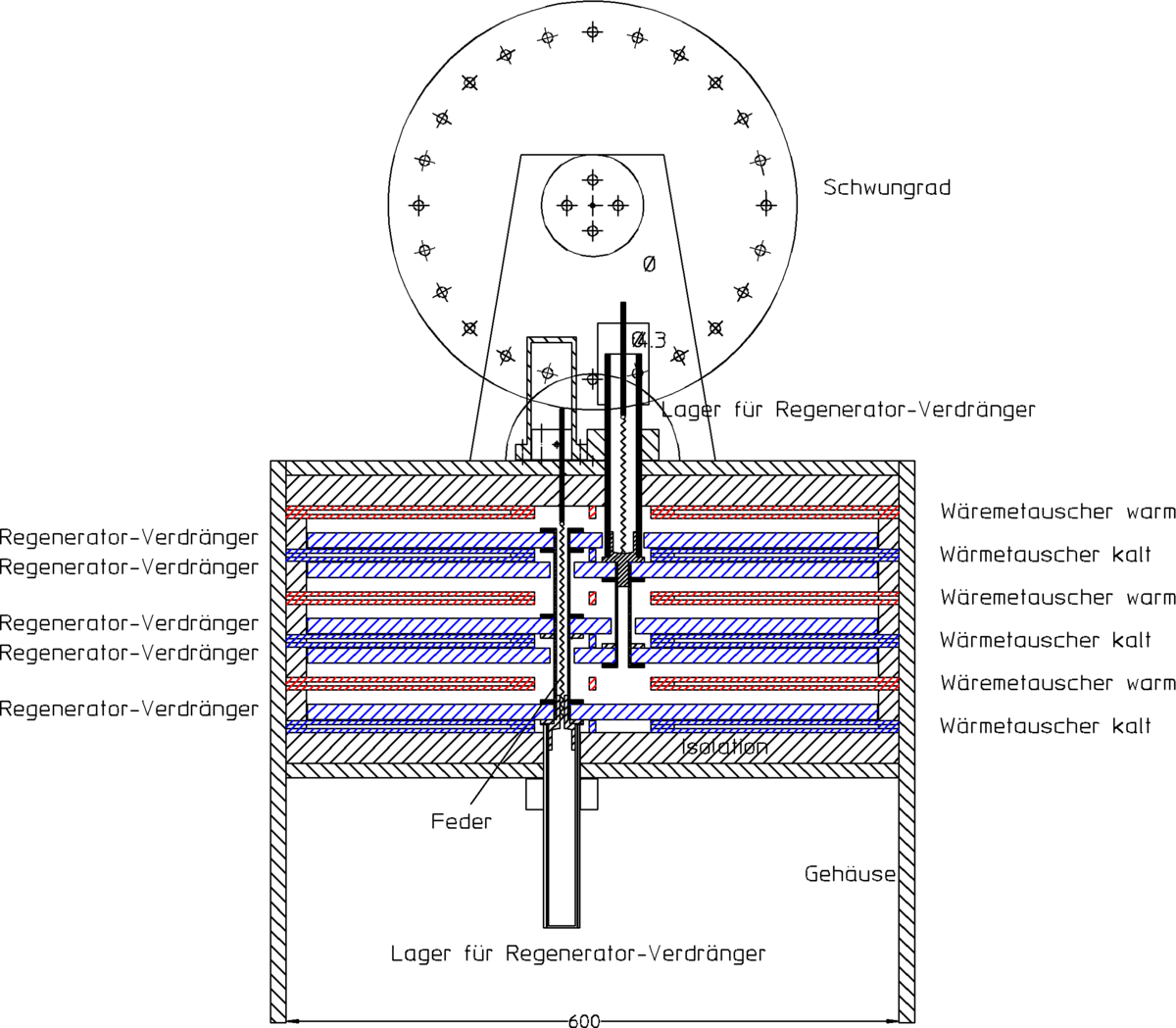

New patented design of a low temperature Stirling engine

In order to provide the entire required heat exchanger performance, the entire working volume is divided into individual cells, each of which is bordered by two heat exchanger surfaces. The whole machine consists of a stack of alternating hot and cold heat exchanger plates. The heat is supplied or removed via two separate water circuits through the heat exchangers designed as hollow chamber panels. By stacking the exchanger plates, the entire required exchanger area can be accommodated in a compact machine. In between are the actual air-precipitated working volumes in which the displacement plates move back and forth discontinuously (due to cyclical pressure fluctuations - ring bomb coupling) and so the air periodically flows towards the warm or cold exchanger plates. This results in periodic heating or cooling of the working gas.

There are two separate displacement stacks. These stacks mechanically connect the displacement plates, which must move synchronously. The two stacks of plates are mounted separately on the top and bottom plates in order to achieve their opposite movement.

The individual cells are pneumatically coupled and perform work on a common working piston. According to the original Kolin idea, this is designed as a membrane with a working connecting rod and coupled to a flywheel on which mechanical work can be carried out. A patent was granted for this idea. The corresponding publication patent DE 195 34 379 A1 can be downloaded as a PDF document.

5. Patent

Thermodynamische Maschine, die nach dem Stirling-Prozeß betreibbar ist

Declarant

Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V.

Inventor

Schmidt, Thomas, Dipl.Phys., 79104 Freiburg

Disclosure document

DE000019534379A1